The FASS Fuel System is a high-performance upgrade for 5.9 Cummins engines‚ designed to improve fuel delivery and engine performance by providing consistent fuel pressure and flow.

1.1 Overview of the FASS Fuel System

The FASS Fuel System is a high-performance fuel delivery solution designed for the 5.9L Cummins engine‚ addressing common issues like low fuel pressure and contamination. It replaces the stock fuel system with a more robust setup‚ ensuring consistent fuel flow and pressure. The system includes an electric lift pump‚ fuel filter‚ and high-quality fuel lines‚ all working together to provide clean‚ pressurized fuel to the engine. This design eliminates air in the fuel lines and reduces the risk of fuel starvation‚ especially under high-demand conditions. The FASS system is engineered to improve engine performance‚ increase fuel efficiency‚ and enhance overall reliability. Its compact and durable construction makes it a popular upgrade for both daily drivers and heavy-duty applications. Proper installation ensures optimal performance and longevity of the system.

1.2 Benefits of Upgrading to a FASS Fuel System

Upgrading to a FASS Fuel System provides numerous benefits‚ including improved fuel pressure consistency‚ reduced contaminants‚ and enhanced engine performance. The system eliminates fuel starvation issues‚ especially during high-demand driving conditions‚ ensuring smooth operation. By providing clean‚ pressurized fuel‚ it reduces wear on the engine and fuel injection system‚ leading to increased longevity. Additionally‚ the FASS system improves fuel efficiency and overall engine reliability. Its robust design ensures durability and resistance to common fuel system failures. Whether for daily driving or heavy-duty applications‚ the FASS Fuel System delivers a noticeable improvement in power and performance. The upgrade is a cost-effective solution to address stock fuel system limitations and is compatible with a wide range of Cummins 5.9L engine configurations. Proper installation ensures these benefits are fully realized‚ making it a worthwhile investment for diesel engine enthusiasts.

Pre-Installation Requirements

Before installing the FASS Fuel System‚ ensure you have all necessary tools and materials. Read the installation manual thoroughly to understand the process. Verify the correct FASS system is selected for your 5.9 Cummins engine to avoid severe engine damage. Inspect the vehicle’s fuel system for any existing issues that may interfere with installation. Clean and prepare the fuel lines‚ ensuring they are free from debris. Apply oil to fittings and inside fuel lines when using Push-Lok connectors. Secure the vehicle to prevent movement during installation. Proper preparation and adherence to instructions are critical for a successful and safe installation. Ensure all steps are followed carefully to avoid system malfunctions and maintain optimal performance.

2.1 Tools and Materials Needed

To successfully install the FASS Fuel System‚ you will need a variety of tools and materials. Start with basic tools like wrenches‚ pliers‚ and screwdrivers. Specialized tools may include a fuel line cutter and flare tool for proper fuel line connections. Ensure you have a set of Torx and Allen wrenches for specific bolts. Additionally‚ gather materials such as Teflon tape‚ oil for fittings‚ and new fuel line components. A bottle jack and jack stands are necessary for lifting the vehicle bed during draw straw installation. Protect the work area with drop cloths to prevent damage from fuel spills. Have a clean‚ well-ventilated workspace and wear protective gloves and eyewear. Make sure all components from the FASS kit are accounted for before starting. Check the installation manual for any specific tools or materials recommended by the manufacturer. Proper preparation ensures a smooth installation process.

2.2 Pre-Installation Checks and Precautions

Before starting the installation‚ ensure you have read all instructions thoroughly to avoid mistakes; Improper installation can lead to severe engine damage‚ so double-check that the correct FASS pump is selected for your 5.9 Cummins engine. Secure the vehicle on level ground and apply the parking brake to prevent any movement during installation. Clean the fuel system to remove debris‚ as contaminants can damage the new components. Flush and inspect fuel lines before connecting them to the FASS system. Use oil on all fittings and inside fuel lines when installing Push-Lok fittings to ensure proper sealing. Disconnect the battery to prevent electrical issues while wiring the lift pump. Ensure all factory fuel system components are in good condition before integrating the FASS system. Proper preparation and caution will help ensure a successful installation.

Installation Process

The FASS system installation involves mounting the pump‚ wiring the lift pump‚ and configuring fuel lines. Follow the manual for proper connections and priming procedures.

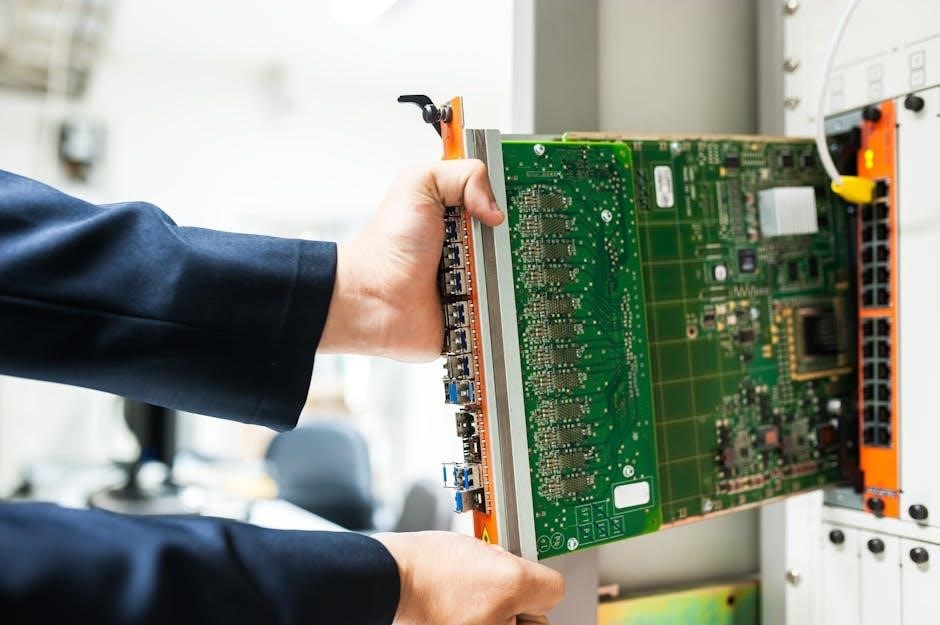

3.1 Mounting the FASS Pump and Fuel Filter

Mounting the FASS pump and fuel filter requires careful planning to ensure proper clearance and accessibility. Begin by selecting a suitable location‚ typically along the frame rail‚ to avoid heat sources and potential damage; Secure the pump assembly using the provided hardware‚ ensuring all bolts are tightened evenly. Next‚ install the fuel filter in an accessible location‚ preferably near the pump for easy maintenance. Use oil on Push-Lok fittings to ensure a leak-free connection. Flush and clean all fuel lines and fittings beforehand to prevent debris from entering the system. Properly align and secure all components to avoid vibration damage during operation. Always refer to the installation manual for specific torque specifications and mounting recommendations. Ensure the system is grounded to prevent electrical issues. Double-check all connections before proceeding to the next step.

3.2 Wiring the Lift Pump

Wiring the FASS lift pump requires careful attention to ensure proper function and safety. Start by connecting the positive wire from the pump to the battery using a 20-amp fuse. Use the factory-supplied wiring harness to connect the pump to the truck’s electrical system. The ground wire should be securely attached to a clean metal surface on the chassis. For proper operation‚ install a relay to manage power distribution‚ ensuring the pump activates only when the engine is running. Route all wires away from heat sources and moving components to prevent damage. Consult the FASS installation manual for specific wiring diagrams and torque specifications. Double-check all connections for tightness and integrity before starting the engine. Proper wiring ensures reliable fuel system performance and prevents potential electrical issues. Always test the circuit with a multimeter to confirm functionality.

3.3 Fuel Line Setup and Configuration

Proper fuel line setup is critical for the FASS system to function efficiently; Begin by connecting the FASS pump to the fuel tank using the supplied 1/2″ blue fuel line‚ ensuring all fittings are securely tightened. Apply a small amount of oil to Push-Lok fittings before installation to prevent damage. Route the fuel line away from heat sources and moving components to avoid damage. Connect the other end of the fuel line to the engine’s fuel inlet port‚ using the factory-supplied T-connector if necessary. Prime the system by turning the key to the “on” position without starting the engine‚ allowing the pump to fill the lines. Ensure all connections are leak-free and secure. Finally‚ double-check the routing to confirm the lines are properly insulated and protected from abrasion. This setup ensures consistent fuel flow and optimal engine performance.

Post-Installation Steps

Prime the fuel system by turning the key to “on” to fill lines. Check for leaks and test system operation to ensure consistent fuel flow and pressure.

4.1 Priming the Fuel System

Priming the FASS Fuel System is essential before starting the engine to ensure proper fuel flow and pressure. Begin by turning the ignition to the “on” position to activate the lift pump. Allow the system to pressurize and circulate fuel through the lines. Use the factory supplied fuel system with a T to the blue FASS 1/2 supply tube for priming. Check for any leaks or air bubbles in the lines. If no issues are found‚ start the engine and monitor for consistent fuel flow and pressure. Proper priming ensures the FASS system operates efficiently and prevents potential damage from air pockets or low fuel pressure.

4.2 Testing the Fuel System

After priming‚ test the fuel system to ensure proper functionality. Start the engine and let it run at idle for a few minutes. Check for any leaks at connections and fittings. Use a fuel pressure gauge to verify pressure levels match the manufacturer’s specifications. Monitor the system for consistent fuel flow and pressure. If equipped‚ use the factory supplied T to the blue FASS 1/2 supply tube to confirm fuel circulation. Listen for unusual noises or vibrations‚ which could indicate air pockets or improper installation. Flush and clean all brass fittings and fuel lines to prevent debris from entering the system. Proper testing ensures the FASS system operates efficiently and prevents potential engine damage from low fuel pressure or contamination.

Maintenance and Troubleshooting

Regularly inspect fuel lines and connections for leaks. Clean or replace the fuel filter as needed. Monitor fuel pressure with a gauge to ensure optimal performance. Address any low pressure or air in the system promptly to avoid engine damage. Consult the manual for troubleshooting specific issues.

5.1 Regular Maintenance Tips

Regular maintenance is essential to ensure the optimal performance of your FASS Fuel System. Start by flushing the fuel lines to remove any debris or contaminants. Inspect all connections and fittings for signs of wear or leaks‚ and tighten them as needed. Lubricate Push-Lok fittings with oil during installation to ensure a secure seal. Clean or replace the fuel filter every 10‚000 to 15‚000 miles to maintain proper fuel flow. Additionally‚ monitor the fuel pressure using a gauge and address any significant drops or fluctuations promptly. Finally‚ consult the FASS manual for specific maintenance schedules and recommendations tailored to your system. Regular upkeep will help prevent issues and ensure long-term reliability.

5.2 Common Issues and Solutions

Common issues with the FASS Fuel System include air entering the fuel lines‚ low fuel pressure‚ or improper pump installation. To address these‚ ensure all connections are secure and free of debris. If air is present‚ prime the system thoroughly; Low fuel pressure can often be resolved by checking the fuel filter for blockages or replacing it if necessary. Improper pump installation may require re-aligning the pump or consulting the manual for correct mounting procedures. Additionally‚ wiring issues can cause the lift pump to malfunction; verify that all connections to the battery and engine are secure. Regularly flushing fuel lines and inspecting for leaks can prevent many of these problems. Always refer to the FASS manual for specific troubleshooting steps tailored to your system.

The FASS Fuel System for the 5.9 Cummins engine offers a reliable solution to enhance fuel delivery and overall engine performance. By following the installation instructions carefully‚ ensuring proper setup‚ and maintaining the system regularly‚ drivers can enjoy improved fuel efficiency and reduced engine wear. It is crucial to adhere to the manufacturer’s guidelines to avoid potential damage and ensure optimal functionality. Regular maintenance‚ such as filter replacements and system checks‚ will extend the lifespan of the FASS Fuel System. With proper care‚ this upgrade can significantly enhance the performance and reliability of your 5.9 Cummins engine‚ providing a smoother and more powerful driving experience. Always refer to the official FASS installation manual for specific details and troubleshooting guidance.